DUST AND AMBIENT AIR MONITORING

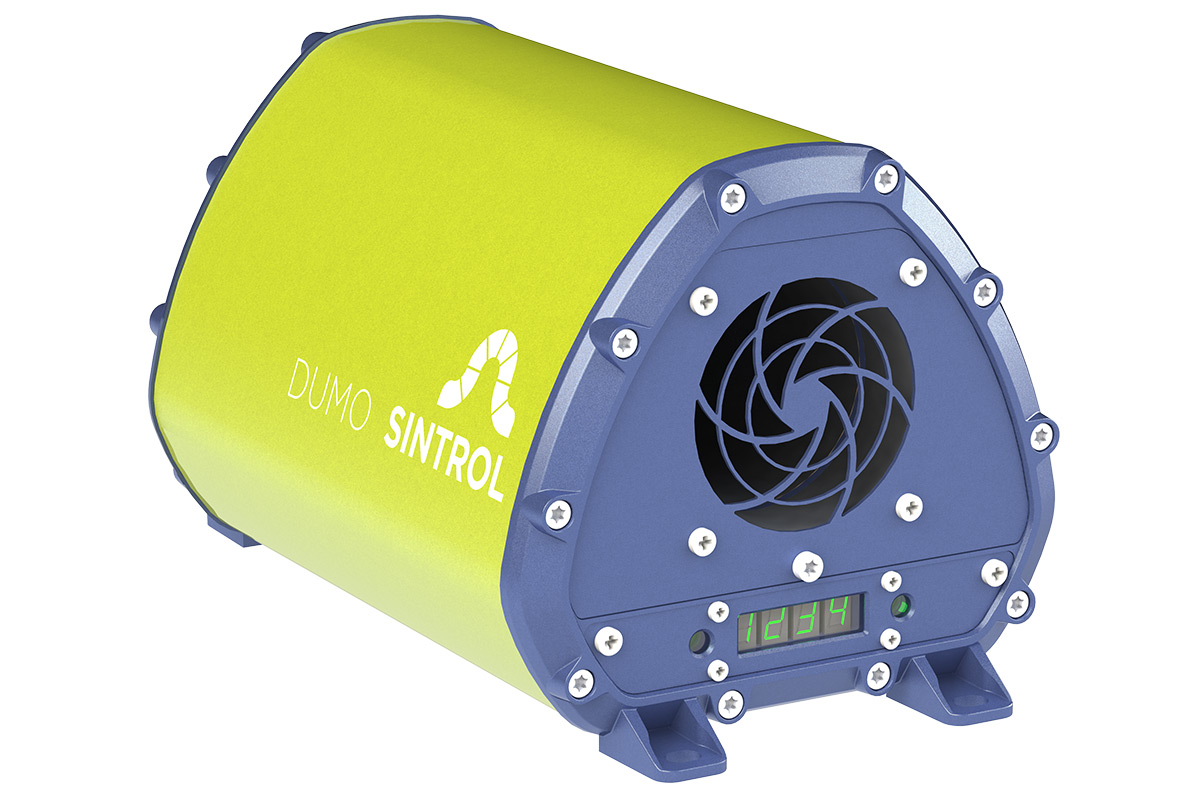

DumoPro

DUST AND AMBIENT AIR MONITORING

Benefits:

• Easy start-up and commissioning

• Wide measurement range

• Internal self-monitoring for failsafe operation

• Fast response time

• No sample handling required

• Product loss prevention

Applications:

• Equipment and worker protection

• Supports good housekeeping practice

• Hazardous location supervision

• Helps mitigate the risk of dust explosion

Low maintenance real-time monitoring of total suspended particles in industrial environments.

Designed to industrial standards with built in failsafe features to increase reliability.

The DumoPro is a powerful tool for measuring dust concentration in industrial environments because of its high sensitivity to total suspended particles. The field proven, state-of-the-art measurement technology, is tolerant to sensor contamination, making it reliable in a wide variety of dust detection applications.

The robustness of the DumoPro makes it a safe choice for dust monitoring in rugged industrial environments. Common industries are flour and sugar mills, mining, wood products, grain handling, chemical, power plants or any bulk and powder handling facility. Some common applications include: health & hygiene, equipment safety, good house-keeping, help mitigate the risk of dust explosions, HazLoc monitoring and the detection of unwanted eventsS303 Process Monitor & S304 Emissions Monitor

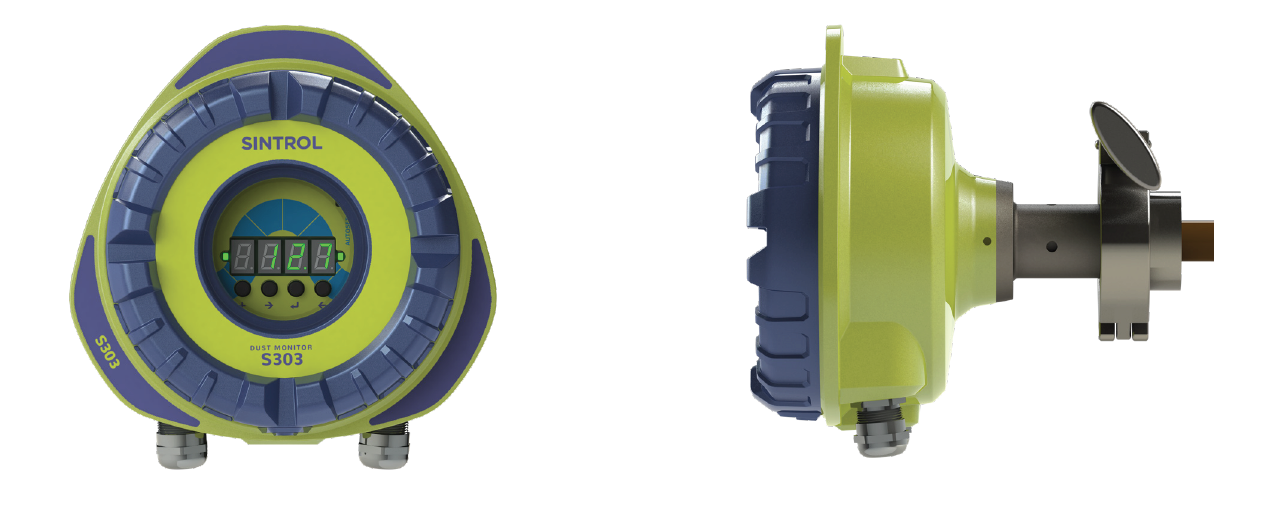

• Easy start-up and commissioning

• Rugged design for harsh industrial conditions

• Proven technology

• Accurate dust measurement

• Extremely wide measurement range

• Detection limit of 0,01 mg/m3

The S300 series is often used for process control in applications where the dust levels need to follow designated limits. The onboard relays of the S300 series can be used as a dust level ALERT / ALARM signal. The mA output and the RS485 interface makes the instrument ideal for trend monitoring applications.

Very short response time is a typical characteristic of these dust monitors, enabling early detection of malfunctions in the dust removal process and prevention of expensive product loss to the environment.

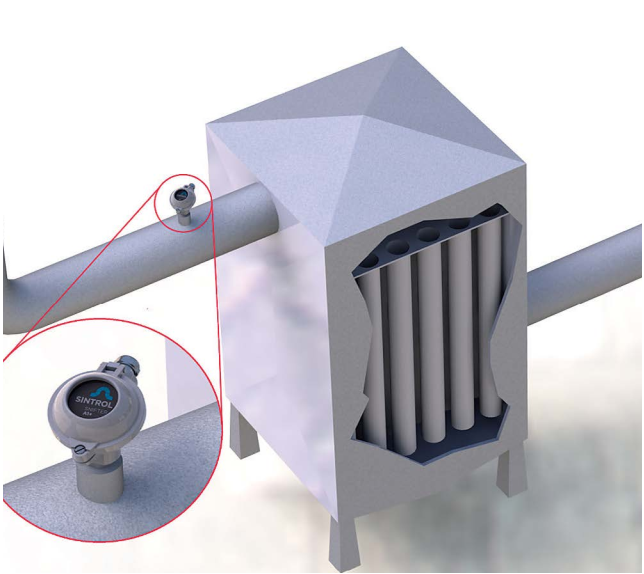

It can be installed into process applications like baghouse, cyclone, dryer or other dust collection systems to monitor particulate emissions as well as filter performance.

Sintrol Snifter - Broken Bag Detection

• Low Cost

• Relative Trend Measurement

The S300 series is often used for process control in applications where the dust levels need to follow designated limits. The onboard relays of the S300 series can be used as a dust level ALERT / ALARM signal. The mA output and the RS485 interface makes the instrument ideal for trend monitoring applications.

Very short response time is a typical characteristic of these dust monitors, enabling early detection of malfunctions in the dust removal process and prevention of expensive product loss to the environment.

It can be installed into process applications like baghouse, cyclone, dryer or other dust collection systems to monitor particulate emissions as well as filter performance.