ROXON HX270

LASER 3D ON-LINE CONVEYOR BELT MONITORING

The technology detects ALL types of belt damage.

THE TECHNOLOGY DETECTS:

• Steel cord splice integrity

• Steel cord damage

• All belt rips and cuts

• Extensive wear

• Cracks

• Edge damage

• Splice damage

Belt damage can cause unscheduled production stoppages,

decreased belt lifetime and substantial repair work. In

addition, belt failures present serious safety risks.

LASER 3D ON-LINE BELT SURFACE SCANNING

The Belt Condition Monitoring System scans the

material and clean sides of the belt. Sensors are located

in optimal positions e.g. loading chutes and unloading

points, which are the most critical positions where the

conveyor belt can sustain damage.

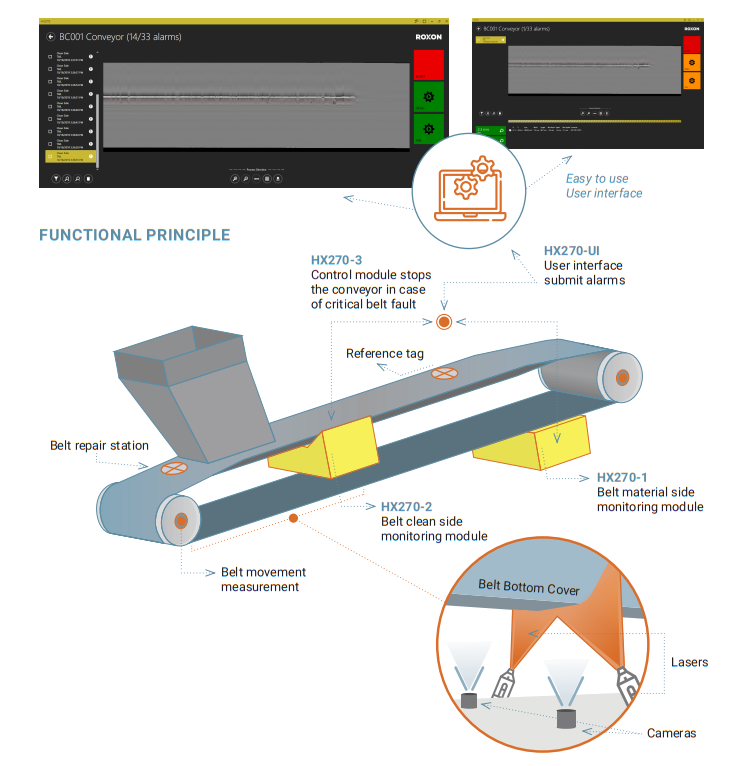

FUNCTIONAL PRINCIPLE

The system is remotely monitored from a control room.

Monitoring laser scanning sensors are connected to

control modules through LAN networks. The system

alarm, conveyor control and status signals can be

integrated into any SDADA and/or control systems.

The system has a reference point to identify exact

positions for repairs, therefore no loops, coils or

modifications to the belt are needed. Selected belt faults

can be automatically driven to a belt repair station.

SERVICE LEVEL AGREEMENT

A Service Level Agreement (SLA) comes as part of the

package providing real-time monitoring and repairing

of faults. This guarantees full-time remote support and

fault analysis.

ROXON HX270 LASER 3D ON-LINE CONVEYOR BELT MONITORING

FEATURES:

• Stops the belt when critical belt damage is detected.

• Early detection of damage enables predictive repair planning.

• Based on laser 3D measurement technology for monitoring both fabric and steel cord belts.

• Offers automatic scanning without constant monitoring by an operator. Automatic alarming on error detection.

• Modular structures ensure expandability.

• Applications available for single conveyors or entire conveyor belt systems. (Long conveyors)

BENEFITS:

IMPROVED CONVEYOR PRODUCTIVITY

• Avoids production loss by stopping belts immediately when critical belt faults are detected.• Early fault detection prevents catastrophic belt failures

LONGER SERVICE LIFE OF CONVEYOR BELTS

• Proactive belt maintenance with on-line belt wear monitoring. Real time belt fault detection and repair.REDUCTION IN STOCK HOLDING

• Real time monitoring and maintenance allows a significant reduction in stock holding of spare conveyor belts.BETTER UTILISATION OF MAINTENANCE STOPPAGES

• Non-critical faults can be repaired at once with proper planning and reduced downtime.IMPROVED SAFETY AT WORK

• Undetectable hazardous belt faults can present a serious safety risk.• Repairs can be planned and carried out in a safe and controlled manner

ROXON HX270 LASER 3D ON-LINE CONVEYOR BELT MONITORING

VISUALISATION OF FAILURES - EXAMPLE - RIP DETECTION

• “Scalpel” rock pierced the belt in the loading chute and the belt ripped.

• HX270 stopped the conveyor immediately and damages were minimised.